The Importance of the Ubolt

When we talk to customers about suspension we always put some emphasis on the humble Ubolt.

A very important part of the suspension because if you have leaf spring suspension the ubolts HOLD your leaf springs ONTO the differential of your vehicle, and your differential houses the axles which your wheels are bolted to and their good mates tyres hold you to the road.

All these questions answered in this video.

7 Important Questions About Ubolts…

1.What shape is the ubolt?

2. What size material has been used?

3. What is the inside measurement of the ubolt?

4. What length are the legs of the ubolt?

5. How much thread does your ubolt have on each leg?

6. What grade material should the ubolts be made of?

7. What if the ubolts I need aren’t available off the shelf?

All these questions answered in this video.

When springs repair or replacement is necessary some people give ubolts little thought because they are planning to save a dollar and “just use the old ones” which sounds like a plan until…

•The old ubolts are seized on and have to be cut off when removing the springs for repairs or replacement

•The old ubolts break or snap under the force used to undo the nuts

•Or the ubolt threads are damaged when the nuts are removed and if re-used keeping the nut TIGHT after reassembling cannot be guaranteed & LOOSE Ubolts will void a new spring warranty

•Or OOPS!….. Forgot that a stronger and therefore thicker leaf spring pack is now being used so my old Ubolts aren’t long enough.

Rest assured your disappointment will be amplified if you are doing the job on the weekend when everything is closed or if you are a long way from the supplier. So to avoid being disappointed by any of these possibilities, let’s just say it is a wise practice to REPLACE the ubolts when a spring removal or replacement has been done.

It is also recommended that the ubolts be re-tensioned 7-10 days after installation as the spring settles into position and any initial stretching of the ubolt threads has occurred. The re-tension will ensure the leaf spring remains firmly secured and is not allowed to rock in place causing unwanted spring flex in the middle of the spring which can cause leaf breakages to occur. Loose ubolts can also cause a leaf spring to walk out of position which will damage your centre bolt and affect the alignment of the vehicle.

Remember….. centre bolts hold the spring together for assembly and help locate the spring onto the axle in the correct position. Correctly tightened ubolts are what holds the springs firmly in place on the vehicle when driving.

So now that you know WHY you need to replace the ubolts, let’s have a look at what we need to know about the ubolt when we are ordering new ones.

Most times just supplying the vehicle make, model and year will be enough. Other times the vehicle or spring specifications have changed and you need to describe the physical properties of the ubolt.

1. What shape is the ubolt?

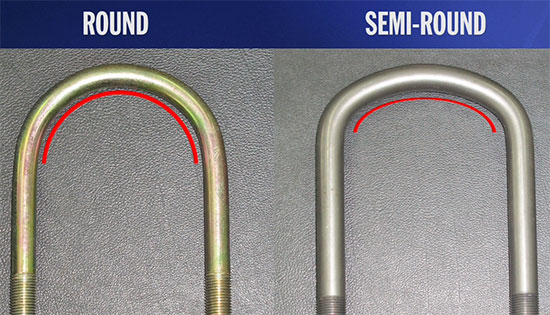

The middle of the ubolt will be formed to go over or under the differential or the mount plate and it will most times be one of a few basic shapes square, round and semi-round.

Pay particular attention to the difference between round and semi-round. Seen together it is much easier to tell the difference. See that the round one is almost a perfect semi-circle shape whilst the semi-round one has only a slight arch.

Further variety exists still if the shape has been forged from round material to be flat so we then have square forged, round forged or semi-round forged. There are also some semi-round designs that are vehicle make/model specific and special dies are required to achieve these shapes but they are not so common.

2. What size material has been used?

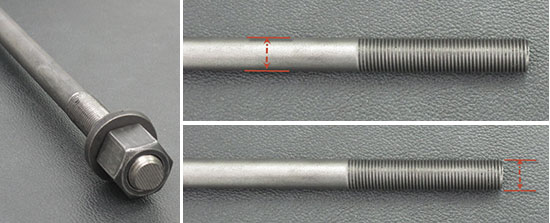

The material used to make the ubolt will be round because the end of the ubolt needs to have a nut thread on to it. So when you are asked what material, you will need to measure the diameter of the rod AT THE THREAD. This is because most ubolt threads are rolled, not cut and the rolling process will make the thread measure as a bigger diameter than the rod itself and if you need nuts to suit measure the thread size …. not simply the rod size.

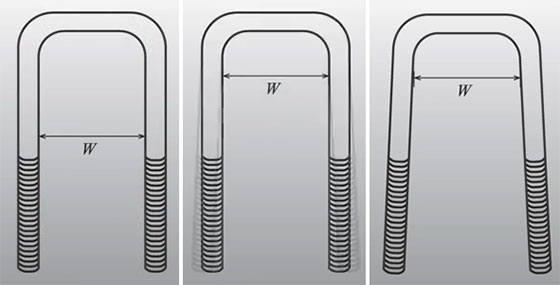

3. What is the inside measurement of the ubolt?

This measurement is critical because it must be the correct width to go over the diff housing or spring pack. Too narrow obviously won’t fit on and too wide won’t secure the spring correctly or fit into the holes of the spring mount cradle or plate. Measure from the inside of one ubolt leg across to the other. Always measure at the shaped end of the ubolt as the legs of the ubolt may spread during removal and give you a larger and incorrect reading.

4. What length are the legs of the ubolt?

When measuring the leg length of your ubolt always measure from the under side of material at the top down to the end of the leg.

Now don’t forget that this is the measurement of the ubolt you have now and you may need to order longer ones if you are adding a packer plate or extra leaf to your spring to add height or strength.

It’s a good tip to have a peak how much thread is sticking out of your original ubolts BEFORE you take them off so you know if your new ones will need to be longer once you have done your additions. Remember that you must have a full nut + two threads extra on the thread of your ubolt exposed after the nut.

Any less and the nuts could work loose. And if you do replace your ubolts,give them a re-tighten approximately 7 days after to make sure any initial settle in of the springs and ubolts has occurred. Ubolts must be tight or problems will occur.

5. How much thread does your ubolt have on each leg?

Most of the time the length of the thread is relevant to the length of the leg with plenty to spare but if you are asked for it, know where to measure.

6. What grade material should the ubolts be made of?

This is not normally something you will need to stipulate. Usually the supplier will know relevant to material size and what the standard requirement is. Some of the smaller 2wd/4wd ubolts are equivalent to Grade 5 whereas the big heavy ubolts are supplied as Grade 8.

7. (6:29) What if the ubolts I need aren’t available off the shelf?

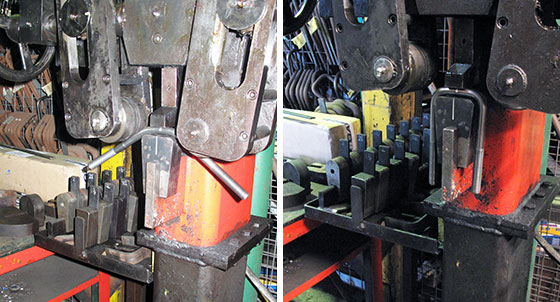

Many suspension suppliers and installers have a ubolt bending machine on site. With the use of one of these machines a ubolt blank can be selected considering the material size, width and leg length you need and bent to the shape or form stipulated for the top of the ubolt.

It is then a case of selecting the right “die” to form the shape needed to make your ubolt.

Individual machines will have limitations on the diameter of rod they can bend. Please remember that threaded rod blanks are a cold bend steel material and it is a definite no-no to use heat on the threaded rod blank to help with the bend. Using heat can cause a reduction in strength or failure of the ubolt.

Hopefully that tells you enough so you can talk ubolt language when asked and you can order your ubolts without too much difficulty.

If you would like a smoother ride in your vehicle or improve the suspension in your vehicle give us a call 1800 630 411 or fill out the form below.