Guaranteed Solution to known problem with Ford F250/F350 models…

Ford F250 & F350 Leaf Spring Solution for four-wheel drive fitted with a three leaf parabolic spring on the front suspension.

Ford F250 & F350 Leaf Spring Solution for four-wheel drive fitted with a three leaf parabolic spring on the front suspension.

Owners of the F250 and F350 trucks will be frustrated by the fact that the front two leaf factory parabolic springs are just not strong enough to handle our terrain whilst carrying a load, plus winch, plus bull bar.

You have probably tried multi-leaf options too and were disappointed because they either lost their shape and sagged or were too harsh a ride for your liking.

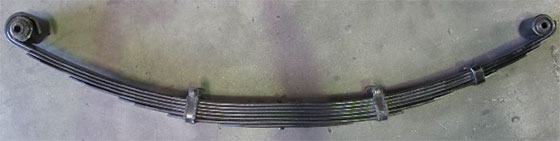

BlueMax has developed a 3 leaf parabolic spring that offers the perfect balance of ride and load carrying ability. You can go from a 2 leaf spring parabolic to a 3 leaf parabolic spring without sacrificing ride and still getting a good 50mm lift in the front.

NOTE: ALL IMPROVEMENTS ARE DESIGNED WITHIN THE VEHICLE’S LEGAL LIMITS.

Watch this video and see how SSA came to find this suspension solution.

Occasionally in the suspension industry, a vehicle make or model will present itself as one that needs its suspension modified to totally remove existing design issues. It’s just not right as it is and the owner experiences ongoing grief trying to fix the ride and sometimes the ride height.

Here is the Ford F250 & F350 four wheel drive fitted with a two-leaf parabolic spring on the front suspension. They have been a popular choice of vehicle for many people wanting the bigger load and towing capabilities that these vehicles offer.

One of this vehicle’s shortcomings however, is that the two leaf parabolic spring in the front, is inadequate and gives up under the load of the big engine and the sometimes fitted front bull bar, and maybe even a big heavy winch.

Impact loading in rough terrain also contributes to the flattening of the spring and worsening of the ride.

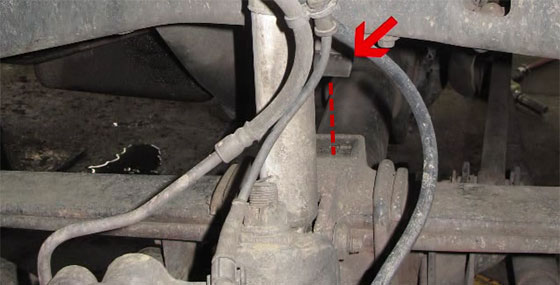

Just look at the backward bend showing in the vehicle’s front spring.

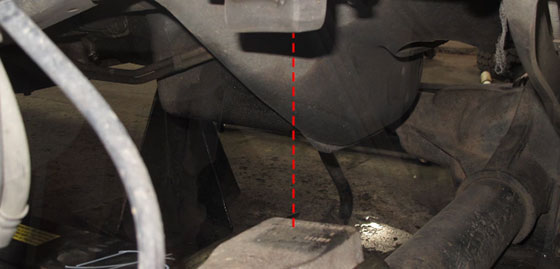

And look how low down in the front this vehicle is and how flat the overall suspension looks.

With the front wheel removed we can see even clearer now how the spring has flattened and inverted.

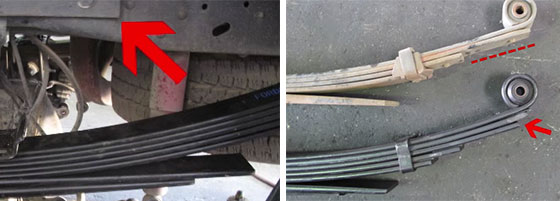

First the front section of the spring – And then the rear section of the spring

Most manufacturers will say that parabolic springs are meant to invert in operation and this is part of the soft supple ride that the parabolic spring provides. This works in theory and very well in fact on flat concrete highways that feature no bumps. But look here at how close the bump stop is to the bump point. It’s not hard to imagine the sort of terrain that would bring that bump stop into play now is it.

See how shiny the bump point is. That means the suspension is inverting regularly and the resultant “bump” would NOT be a desirable ride feature.

Many in the suspension industry have developed a “multi-leaf spring” as a replacement option for the two leaf parabolic spring.

SSA also developed a couple of designs but as we had an F250 and an F350 in our company fleet we had plenty of time to evaluate these springs. BlueMax

It was determined that the ride comfort was far better in the parabolic design. We just needed to improve the strength and the camber height and after many months of trials on a number of vehicles, we developed a three leaf parabolic spring to replace the two leaf version.

That’s basically 50% stronger. Cambered correctly this gave us the height and strength that many customers are looking for. The new third leaf provides additional support right out under the spring eyes at both ends.

We have built a four-leaf parabolic also for some very special cases but this is required only when an extra heavy protection bar has been used. Again you can see the support that the extra leaves offer in this special 4 leaf version.

Here is the 3 leaf set installed – looking better already. Both in the front and in the rear.

Just look at the improved bump stop clearance. There’s one BIG problem gone.

The rear springs on these vehicles never present much of a problem. The choice of spring replacement or modification is usually determined by the condition of the existing springs and the load that the vehicle will carry and whether or not it is a constant load. Sometimes an airbag offers the perfect load assist variation needed for load “ON” and load “OFF” situations like towing a caravan

As you can see, there’s not a lot wrong here except you see some tired rear springs looking very flat and laying down on the second stage with no load in the vehicle at all. The customer reported that towing a horse float sagged the rear significantly and lifted the front causing loss of steering control.

We have opted for a stronger spring as the bracket supporting the 5th wheel turntable does not permit the fitment of airbags to this vehicle. Note the addition of the 3rd leaf and how it supports out under the eye and doesn’t leave the first two leaves with a big gap before any additional support from the spring leaves lower in the pack. And the same for the rear of the spring. Support where it is needed out near the end of the main and wrap leaves.

All set up and back on the ground and you can see we have a nice camber or curve still in the rear spring under load which will give us a nice ride empty and gradually introduce the other leaves in the pack and eventually calls on the second stage to assist.

The end result is well-balanced suspension that has removed front bump out and given us height front and rear that can handle the load stipulated.

So if you want your ‘Effie’ to stand tall and carry your load, call us here at SSA so we can discuss options that will suit your ride, load, and terrain. Call us on 1800 630 411 or complete the form below for an express quote.

NOTE: ALL IMPROVEMENTS ARE DESIGNED WITHIN THE VEHICLE’S LEGAL LIMITS.