Improve Suspension On Isuzu NPS300 4×4 Truck

In some of our other videos we have shown you a variety of ways to improve a four wheel drive, light vehicle suspension to better carry the loads customers want…. and to STILL maintain ride comfort when travelling to those “interesting and sometimes hard to get to places”.

In some of our other videos we have shown you a variety of ways to improve a four wheel drive, light vehicle suspension to better carry the loads customers want…. and to STILL maintain ride comfort when travelling to those “interesting and sometimes hard to get to places”.

In this video below we will show you what we have done to improve the suspension on an Isuzu NPS300 4×4 truck.

The story is the same in that we know the manufacturer has built a suspension that provides traction and load carrying. But some improvements can be made to the ride when the owner makes some changes like a custom fit-out with plenty of fittings and accessories needing more weight carrying capability.

This vehicle has fitted a ‘super single’ wheels and tyre combination to improve the ride and traction

and plans to take this truck places where roads are sometimes optional … so improved suspension articulation will be critical.

Watch this video and see how SSA came to find this suspension solution.

Front Suspension

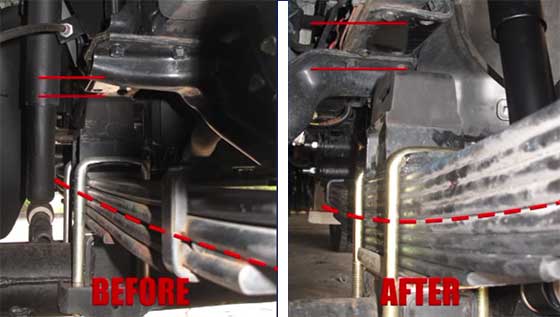

First let’s have a look at what the original suspension make up is. Let’s start at the front. The front has a 4 leaf primary pack plus 1 secondary support leaf. This spring pack design is obviously struggling under the vehicle’s current loaded weight as it is looking relatively flat and the 4 primary leaves laying down permanently in contact with the second stage leaf.

Note also how close the bump stop is to the chassis which means the two will come into contact quite soon when articulating over uneven surfaces or bumps. This original design incorporates the compression of this bump stop as part of the suspension when the spring works hard. The spring will then reverse or bend backwards in such cases and unfortunately will return to it’s normal camber position quite quickly once the load comes off, often throwing around people and contents in the cabin.

Just look at the difference between the two springs. Our BlueMax spring is a more conventional front truck spring design, using more leaves with an altered main leaf length to allow more camber or height in the spring. No second stage leaf…. which has been known to figure in breakages higher up in the pack when the primary lays backwards over the immovable secondary leaf under load.

So let’s take some before measurements for later comparison and get the vehicle ready for front spring replacement. First we need to jack the vehicle up and secure the front air jack stands under the chassis

Then remove the right hand side air box assembly to provide access to the right hand rear shackle and off with the front sway bar to make it easy for spring removal.

The standard “silent block” bushes, comprised of steel / rubber / steel, are removed using a long punch and some gentle persuasion. These will be replaced by urethane bushes with steel tubes. The tubes have been specially modified to ensure grease can be pumped in effectively to reach all possible squeak points of the bush surface.

Once installed in the eye of the spring the width of the combined tube and bush is checked to ensure it will fit neatly into the front eye bracket.

Now the front springs can be lifted into position. Locate the front of the spring into position using the front shackle pin and then the rear of the spring using the rear shackles and pins.

Then correctly locate the spring centre bolt into the axle locator hole. Ready now to fit the ubolts and the front sway bar mount bracket and sway bar itself. Refit the air box and new shock absorbers and get the truck back on the ground. We are set to check the results.

Note the improved curve or camber of our spring under load giving a softer more gradual increase in spring compression. Note also the improved bump stop clearance from the chassis.

From the outside it is clear we have achieved an improved guard arch to wheel rim height and we now know this is because our leaf spring has good shape or camber which is exactly what we had planned for. We can expect a dramatic improvement in ride characteristics as well.

Rear Suspension

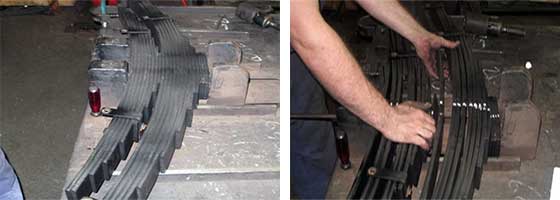

Now we need to address the rear springs. Let’s start with our before measurement. Then we can jack the vehicle up and get it onto chassis stands for removal of the old rear springs. We will be replacing them with stronger spring packs which will improve the rear suspension strength and height.

Our stronger new rear spring packs will not need to feature as many of those, now unnecessary, bottom spring packer plates that have been used to artificially lift the vehicle.

We needed to recamber the new rear springs to suit the special load of this vehicle.

We must also factor in the improvement in front height we have achieved. That is where experience pays off. Our springmaker knows exactly what to do.

Now to lift this heavy 71kg spring into position.

Secure it at the shackle pins both ends – Fit and tighten the ubolts. We also fitted some new Sachs quality truck shock absorbers to help provide improved ride control. Grease application via the shackle pin grease nipple will be checked after installation. A great feature for later service opportunities.

Back on the ground now and our measurements tell us what you can plainly see with the naked eye.

Greatly improved rake of the vehicle even with heavy load on board. Front and rear heights have improved and the vehicle not only looks great, we are now confident it will handle the heavy loads the customer plans to have. We can also be sure the ride will be dramatically improved especially going over the terrain he plans to explore.

NOTE: ALL IMPROVEMENTS ARE DESIGNED WITHIN THE VEHICLE’S LEGAL LIMITS.