Installation Polyair Bellows Spring or Airbag

Polyair produce a load assist air bag for use with leaf springs known as the Polyair Bellows spring or bag. Perfect for use in load on – load off situations like towing a caravan or boat.

Watch this video if you think your rear leaf suspension needs some help when towing or just carrying more load. If you want the same result… give us a call.

1. Load On – Load Off

Polyair Bellows are of heavy duty rubber construction with steel brackets and are engineered to help carry significant loads, right up to manufacturer recommended gross vehicle mass or weight rating. Again perfect for use in “load on” “load off” situations like towing a caravan or boat.

2. Recommendation and Consideration

Before we recommend you fix “ALL” your load carrying requirements with a set of these bellows air bags…. we ask that you consider a couple of things. We at SSA believe that most modern-day vehicles, including 4wds, are not engineered to use the bellows air bag method as a primary load carrier with many pointing to the bellows bag as the cause of chassis damage when in fact it is often misuse that is the major contributor.

3. Consider that the vehicle is designed to carry the rear load at two points of the chassis.

These are at the front fixed pin mount of the spring and at the rear swinging shackle end of the spring. It therefore stands to reason that if loads are significant, consideration should be given to strengthening the leaf spring first and used in conjunction with any bellows air bag support. Once we have strengthened the leaf spring to suit the load we can then choose the appropriate bellows air bag to provide load assist or vehicle levelling.

4. Consider the vehicle’s suspension design which we see is suffering under the loads it is carrying, the customer’s use of the vehicle and the load carrying requirements (towing a caravan and touring) as well as the frequency and variation of these loads. Only then can we determine a design for the leaf spring so the bellows air bag can do its job.

5. Fitment of a Polyair Bellows Air Bag system to suit this customer’s vehicle.

First it’s up on the hoist and wheels off. Then with the diff supported, we remove the ubolts, discard rubber bump stop. (It will not be needed as the air bag has its own internal bump mechanism). Then remove the rear shackles, and front pins and out with the leaf springs.

6. First step is to strengthen the leaf spring. We have chosen to add a 10mm wrap leaf to the pack which is then an “extra leaf”. New spring clips had to made to suit the increased pack thickness. Then trim the ubolt top locator plate to make it easier to tighten the ubolts when the air bag is installed.

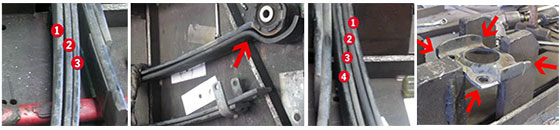

7. Reinstall strengthened leaf spring. While the leaf spring is still out of the vehicle, drill the holes for the air bag top mount plate and tap the threads using a cutting compound as a lubricant.

Time to reinstall our strengthened leaf spring and get our air bag ready to install by screwing in the top inflation point, following the product installation instructions carefully so the fitting is not screwed in too far. Pre-assemble the top mount plate to the bag as well, and fit the air line to the elbow fitting ready to mount the air bag.

8. Locate the top plate bolts and mount the air bag to the chassis. Mount the base of the air bag to the spring mount plate using the longer ubolts which are now necessary because we have made the spring pack thicker with the addition of the extra leaf.

9. Fit protective tubing along critical areas of the air line to provide additional protection where needed. Run the air line along the top of the chassis as far as is practical and secure the air line with zip ties. Leave the air line with excess length at the rear ready to trim to the correct length for our mounting bracket.

10. Find an appropriate mounting point for our inflation valve bracket and secure ready to hook up our air line valves. Prepare the valve end of the air line secure in position on the mounting bracket

11. When not carrying a load you should ensure some air pressure (approx. 10 p.s.i.) should be retained in the air bag to ensure the bag does not pinch or chaffe in the non-inflated position. Follow the supplied air bag instructions to inflate to the recommended pressure for the load you are carrying. The job is now completed and with the strengthened springs doing their job and the minimum of air pressure in our bellows air bags we can see the vehicle is now ready to tow that caravan and the gear that is stored in the canopy.

12. As you can see from the before and after photos there has been a slight lift in the rear suspension of 25mm from the vehicle’s previously sagged position. The height of the rear can of course be adjusted as the load comes on simply by adding more air pressure. More pressure can be added to either side air bag as we have separate air lines and valves to left & right air bellows bags which means any additional fuel, water, gear, equipment or any other contributors to your load can be accommodated and you will sit level and stable on the road.

On board adjustment controls are also available if you prefer in cabin adjustment and monitoring of your air bag pressure.

Give us a call or drop in if you can and let us give you the advice you need to be safe and comfortable on the road.