Japanese Truck Suspension NO MORE BUMPS…

Japanese Truck Suspension NO MORE BUMPS…

Here at Suspension Supplies Australia we regularly hear from drivers of Japanese trucks to do with the problems they have with the truck’s suspension.

The problems presented can feature in Isuzu, Mitsubishi, Hino, Toyota, UD trucks and often it worsens as the truck suspension ages or changes from its originally intended use or load.

Drivers typically say, “It’s too rough a ride” or “It throws me around in the cabin every time I hit a bump or a dip”.

The design and development team have developed a range of solutions to improve the ride and performance of Japanese truck suspensions but first, let us look at the most common causes of sagged or badly performing suspensions for these trucks.

NOTE: ALL IMPROVEMENTS ARE DESIGNED WITHIN THE VEHICLE’S LEGAL LIMITS.

The problem of course, is that the suspensions in these trucks, are usually under sprung for the weight of the vehicle which includes its accessories and fittings as well as the load they carry…… because THESE TRUCKS were designed to operate on smooth highways that do not cause the front leaf springs to articulate or… move up and down very much in operation.

Once these vehicles hit our Australian roads the ride experienced can be less than satisfactory. Just have a look at this set of front springs in a 4×4 model which is typical of what we are talking about in general.

See how flat the springs are which means the springs have already offered their maximum comfort that can be afforded by the gradual introduction of each leaf as the spring flattens. The only flex left now is as the spring inverts or goes backwards beyond its intended flex which will result in a rapid return back up with the full force of the spring in play.

Look also at how close the bump stop is before it bumps out on the chassis. There is hardly any movement before the “bump”. On closer inspection, we can see that “bump out” has been happening all too often because a shiny spot has developed on the bump bracket where the rubber or stop has been continually hitting the chassis mount.

The bump stop being so close will give the driver this hard ride or bump, and the bending backward of the spring at the bump, followed by the all too sudden return back to shape of the spring, will throw the driver around in the cabin. Another thing that can make these symptoms worse, is the two or three leaf – parabolic leaf springs that’s also featured in some light truck models.

Parabolic springs are designed for comfort but if they flatten and invert you get the same end result. Bump & bounce.

So here’s a solution for this set of problems that many of our customers are very happy with.

1. To start with, we have built a stronger spring … and given it more camber. We have a 6 leaf spring against the original 5 leaf. You can see the difference.

2. The third leaf here in our spring is an additional leaf, extending right out under the eye of the main leaf providing maximum support and strength. The end result is that the spring is stronger and has retained camber (not flat) which allows the spring to flex as it should … and … keep the bump stop well away from the bump point.

3. In addition to that… We fit BlueMax urethane bushes together with greaseable shackles and pins instead of the genuine type. You then have added long life serviceability. The end result is an almost perfect shackle angle typical of a sound leaf suspension set up.

4. Then lastly… If you wanted to control the ride, even more, add some quality Sachs shock absorbers. German engineered quality. You can’t go wrong.

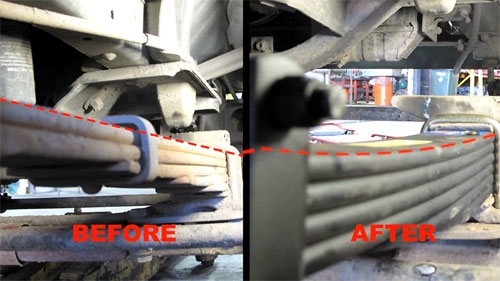

Now everyone is happy. No more bumps. No more throwing around in the cabin. Great ride and stability and superb driver comfort. You will never need to look beyond this proven fix to Japanese truck suspension. See for yourself in these before and after shots how this has raised the vehicle. Look at the difference in the wheel to wheel arch heights.

NOTE: ALL IMPROVEMENTS ARE DESIGNED WITHIN THE VEHICLE’S LEGAL LIMITS.